-

- Forming Fabrics

- We offer 4 kinds of forming fabrics for various applications in the forming section of paper machines.

2.5-layer forming fabrics (8-shed and 16-shed available) and SSB triple-layer forming fabrics (5-shed, 8-shed and 10-shed available).

Individual solutions are proposed to match your conditions and demands, thus reaching higher efficiency for your operation. To work out the best solutions, please contact us with your demands regarding fabric structure, dewatering elements layout, pulp grades, wet end chemistry, machine speed, paper types, and paper grammage, etc. More

-

- Dryer Fabrics

- We offer 4 kinds of dryer fabrics for various applications in the dryer section in paper machines.

Round yarn 1.5-layer dryer fabric (400-500CFM), round yarn 2-layer dryer fabric (500-750 CFM), flat yarn single warp dryer fabric (160-750 CFM) and flat yarn double warp dryer fabric (90-375 CFM).

We have different options suitable for your dryer section, positions, paper grades, paper grammage and machine speed.More

We have an array of experienced experts stand by to provide professional service in fabric application, paper production, technical support, to end product sales.

- Our experts offer concrete solutions which will fit the specific requirements of the forming and dryer section configuration, machine speed, pulp grades, paper types, paper grammage and quality, etc.

- Our technical support team delivers not just mere maintenance, but also tailored optimization measures.

- Our highly qualified sales personnel led by experts are ready to answer any questions you may have regarding fabric specs, application, technical details, customer success story and trainings on various subjects such as safety and fabrics application. etc.

We are committed to working in close cooperation with you in order to promote first-class paper machine clothing!

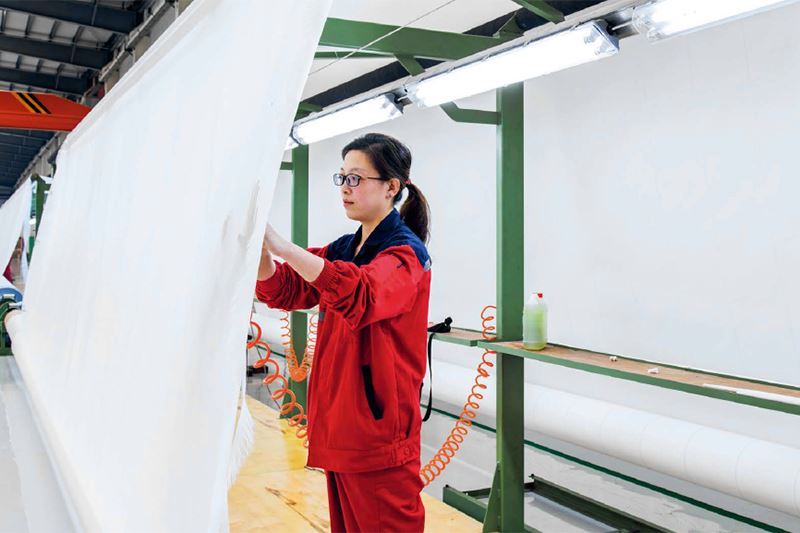

Hehuang established an integrated and standardized production line, ensuring a stable production of paper machine clothing that meets the strictest demands.

- Incoming raw material inspection

- Warp preparation

- Weaving

- Paper-making forming fabric testing

- First heat setting

- Cutting

- Seaming

- Second heat setting and finishing

- Packaging and shipping

We carry out laboratory-level quality check with 17 testing machines including air permeability tester, weave structure analyzer, tension tester, shrinkage tester, abrasive tester and breaking factor strength tester etc. Constant quality tracking and control start from the raw material and continue. Based on many years of experience in the paper machine clothing manufacturing combined with various customer feedbacks, we are confident to provide optimum forming and dryer fabrics for your operation efficiency!

Thorough and comprehensive quality management and monitoring are executed across the entire production of forming and dryer fabrics, including (but not limited to) close-in inspection which cover every inch of the product after each production step in the weaving, heat setting, seaming and finishing department, before the products are packed for transportation.

Once finished, the products will receive a full assessment on all relevant indexes regarding warp yarn and weft density, air permeability, planarity, elongation, seam strength, thickness and so on. Same tests are also carried out during the production, as demonstrated in above picture (air permeability monitoring of a PPS dryer fabric).

We promise that no product with rejected quality will be shipped to our customers.