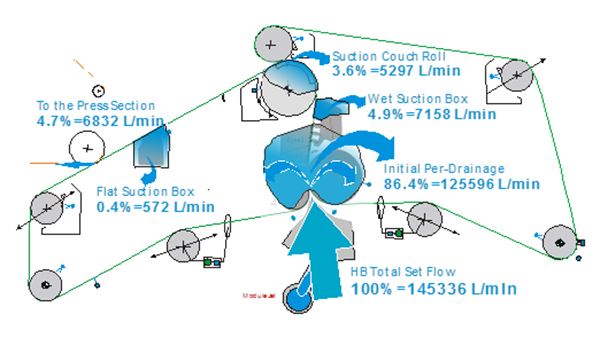

Hehuang provides a wide range of forming fabrics and dryer fabrics for applications in high speed gap former paper machine. In order to work out the best solutions for your forming and dryer sections, please contact and discuss with us your demands based on given information about machine configuration, speed, wet end chemistry, pulp grades, paper types, paper grammage and quality, etc.

SSB triple-layer sheet support and binding design (warp ratio 1:1) is recommended for high speed gap former paper machine. Different weft ratios provided (1:1 /2:1 /3:2).

-

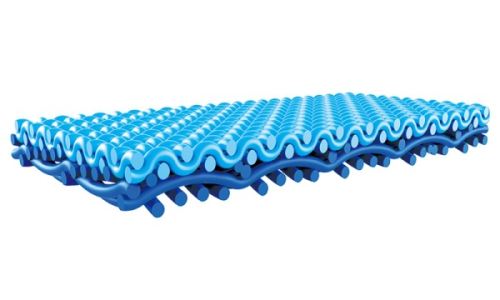

- SSB Triple-layer Forming FabricThis forming fabric with a structure of double-layer warp and double-layer weft with plain weave on sheet side can give the best fiber support and stable size as well as longer life. Compared to older designs, it delivers the richest supporting points on the sheet side, thus enabling an ultra-smoothness surface of end product, high retention, and minimum wire mark.

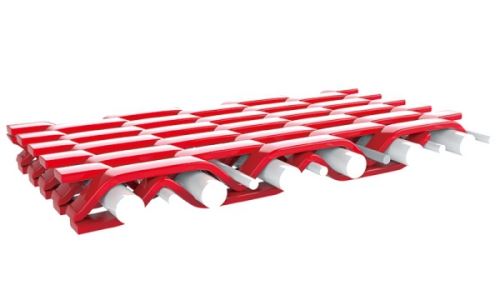

Contact us, and we will select the most suitable dryer fabrics according to the dryer section configuration and speed of your high speed gap former paper machine, paper grades and paper grammage. Here, we recommend the flat yarn double warp dryer fabric.

-

- Double Warp Dryer Fabric (Flat Yarn) Double warp ensures a seamless structure with a flat wire side, leaving barely noticeable seam mark on the sheet. The flat yarn gives great sheet contact for efficient drying and easy cleaning. Its air permeability of 90-375 CFM is eligible for sensitive paper grade. Durability and runnability aren't of much concern thanks to the strong seam and stable structure. On-the-machine cleaning and easy seaming saves you time and effort.

Contact us to discover more customer success stories.

We have an array of experienced experts stand by to provide professional service in fabric application, paper production, technical support, to end product sales.

- Our experts offer concrete solutions which will fit the specific requirements of the forming and dryer section configuration, machine speed, pulp grades, paper types, paper grammage and quality, etc.

- Our technical support team with extensive knowledge and field experience delivers services including not just mere maintenance, but also tailored optimization measures.

- Our highly qualified sales personnel led by experts are ready to answer any questions you may have regarding fabric specs, application, technical details, customer success story and trainings on various subjects such as safety and fabrics application. etc.

We are committed to working in close cooperation with you in order to promote first-class paper machine clothing!

-

- Forming Fabrics

- We offer 4 kinds of forming fabrics for various applications in the forming section of paper machines.

2.5-layer forming fabrics (8-shed and 16-shed available) and SSB triple-layer forming fabrics (5-shed, 8-shed and 10-shed available).

Individual solutions are proposed to match your conditions and demands, thus reaching higher efficiency for your operation. To work out the best solutions, please contact us with your demands regarding fabric structure, dewatering elements layout, pulp grades, wet end chemistry, machine speed, paper types, and paper grammage, etc. More

-

- Dryer Fabrics

- We offer 4 kinds of dryer fabrics for various applications in the dryer section in paper machines.

Round yarn 1.5-layer dryer fabric (400-500CFM), round yarn 2-layer dryer fabric (500-750 CFM), flat yarn single warp dryer fabric (160-750 CFM) and flat yarn double warp dryer fabric (90-375 CFM).

We have different options suitable for your dryer section, positions, paper grades, paper grammage and machine speed.More