Hehuang’s forming and dryer fabrics provide the necessary flexibility to make cardboard production across a broad range of grades. Please contact us to design solutions based on your forming and dryer section configurations, machine speed, wet end chemistry, pulp grades, paper types, paper grammage and quality, etc.

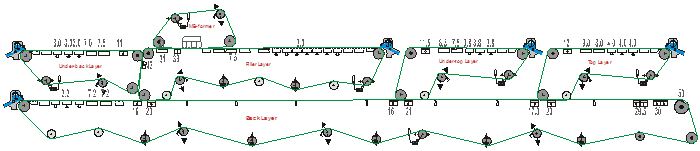

We offer 2 kinds of forming fabrics for multi-fourdrinier board machine, the SSB triple-layer forming fabric and 2.5-layer forming fabric.

-

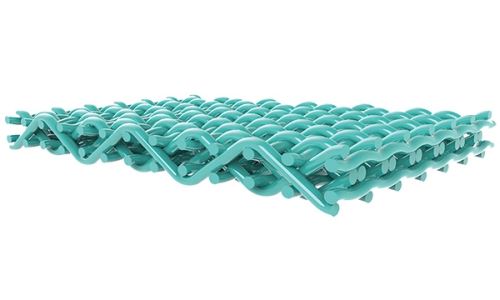

- SSB Triple-layer Forming FabricSSB triple-layer forming fabric exceeds the various demands of the forming section in cardboard machinery. With this well-formed design pattern consisted of double warp yarns and two wefts, come many highlights:

- Excellent surface characteristics as well as improved retention delivered by the maximum fiber support index (FSI) provided by the flat weave pattern

- Steady-state drainage due to open structure

- Prolonged fabric life resulted from dimensional stability

Extra life potential is available from independently selected wefts on diameters, densities and ratio (1:1, 2:1 and 3:2 available).

-

- 2.5-layer Forming Fabric2.5-layer forming fabric has been engineered for multi-fourdrinier board machine. This design uses more wefts on the sheet side than on the bottom side, at a ratio of 2:1, applicable in an extensive product range.

- Surface smoothness, retention and tensile strength from the high FSI provided by rich surface CD yarns

- Excellent drainage and dimensional stability provided by this time-tested structure

- High resistance against wear due to the 8 sheds (16-shed option available) on the wear-side

To satisfy your needs for air permeability in multi-fourdrinier board machine, we offer diversified dryer fabric products.

-

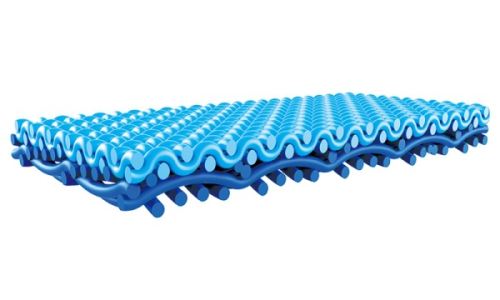

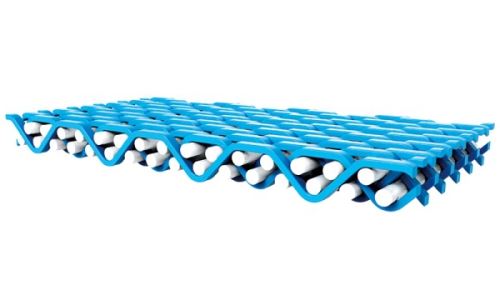

- 1.5-layer Dryer Fabric (Round Yarn)1.5-layer dryer fabric (round yarn) is of high air permeability (500-750 CFM), suitable for all paper grades at industrial level. Comprised of high hydrolysis resistant material, it is especially durable in the face of challenges posed by heat and steam. This weave structure delivers high thermal transfer, dimentional stability, low air carrying, excellent cleanliness and strong seam.

-

- 2-layer Dryer Fabric (Round Yarn) Compared to 1.5-layer design, the 2-layer one allows for the seamless construction of strength, on top of several highlights seen in 1.5-layer design:

- Long potential life guaranteed from high hydrolysis resistant material comprised

- Efficient drying due to the weave structure

- Wide application of high air permeability (500-750 CFM) suitable for all paper types

-

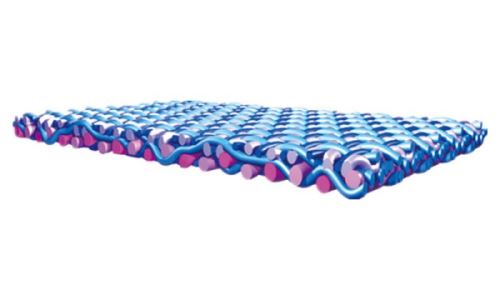

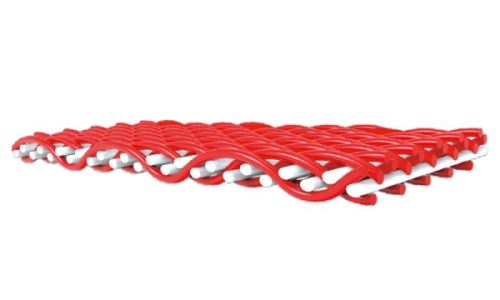

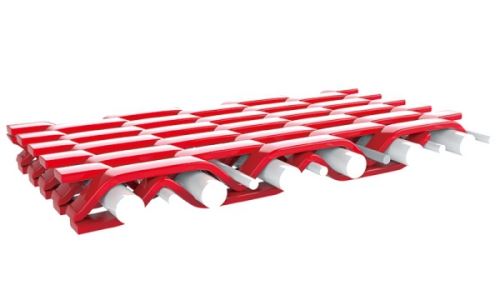

- Single Warp Dryer Fabric (Flat Yarn) Single warp dryer fabric (flat yarn) is a time-tested design with air permeability ranging between 160-750 CFM. On top of high resistance again wear, the flat monofilament also offers smooth and wide contact area, thus high thermal transfer efficiency. The flat machine direction yarn construction allows excellent cleanliness. This pattern leaves almost indistinguishable seam mark, yet, it promises quick and easy seaming with excellent strength. Use our flat yarn single warp dryer fabric for cardboard production, you can have quality products as well as extended fabric durability.

-

- Double Warp Dryer Fabric (Flat Yarn) Flat yarn double warp dryer fabric exceeds the demands for cardboard making. A flat weave structure gives the largest possible contact area with low to medium air permeability (90-375CFM). Therefore, it is easy to clean, efficient in drying and resistant to wear. The double-layer construction allows smooth surface and strong seaming that is identical to the rest of the fabric, leaving no marking on the product. This particular design is less stretchable and rather stable in structure, underpinning further durability.

Contact us to discover more customer success stories.

We have an array of experienced experts stand by to provide professional service in fabric application, paper production, technical support, to end product sales.

- Our experts offer concrete solutions which will fit the specific requirements of the forming and dryer section configuration, machine speed, pulp grades, paper types, paper grammage and quality, etc.

- Our technical support team with extensive knowledge and field experience delivers services including not just mere maintenance, but also tailored optimization measures.

- Our highly qualified sales personnel led by experts are ready to answer any questions you may have regarding fabric specs, application, technical details, customer success story and trainings on various subjects such as safety and fabrics application. etc.

We are committed to working in close cooperation with you in order to promote first-class paper machine clothing!

-

- Forming Fabrics

- We offer 4 kinds of forming fabrics for various applications in the forming section of paper machines.

2.5-layer forming fabrics (8-shed and 16-shed available) and SSB triple-layer forming fabrics (5-shed, 8-shed and 10-shed available).

Individual solutions are proposed to match your conditions and demands, thus reaching higher efficiency for your operation. To work out the best solutions, please contact us with your demands regarding fabric structure, dewatering elements layout, pulp grades, wet end chemistry, machine speed, paper types, and paper grammage, etc. More

-

- Dryer Fabrics

- We offer 4 kinds of dryer fabrics for various applications in the dryer section in paper machines.

Round yarn 1.5-layer dryer fabric (400-500CFM), round yarn 2-layer dryer fabric (500-750 CFM), flat yarn single warp dryer fabric (160-750 CFM) and flat yarn double warp dryer fabric (90-375 CFM).

We have different options suitable for your dryer section, positions, paper grades, paper grammage and machine speed.More